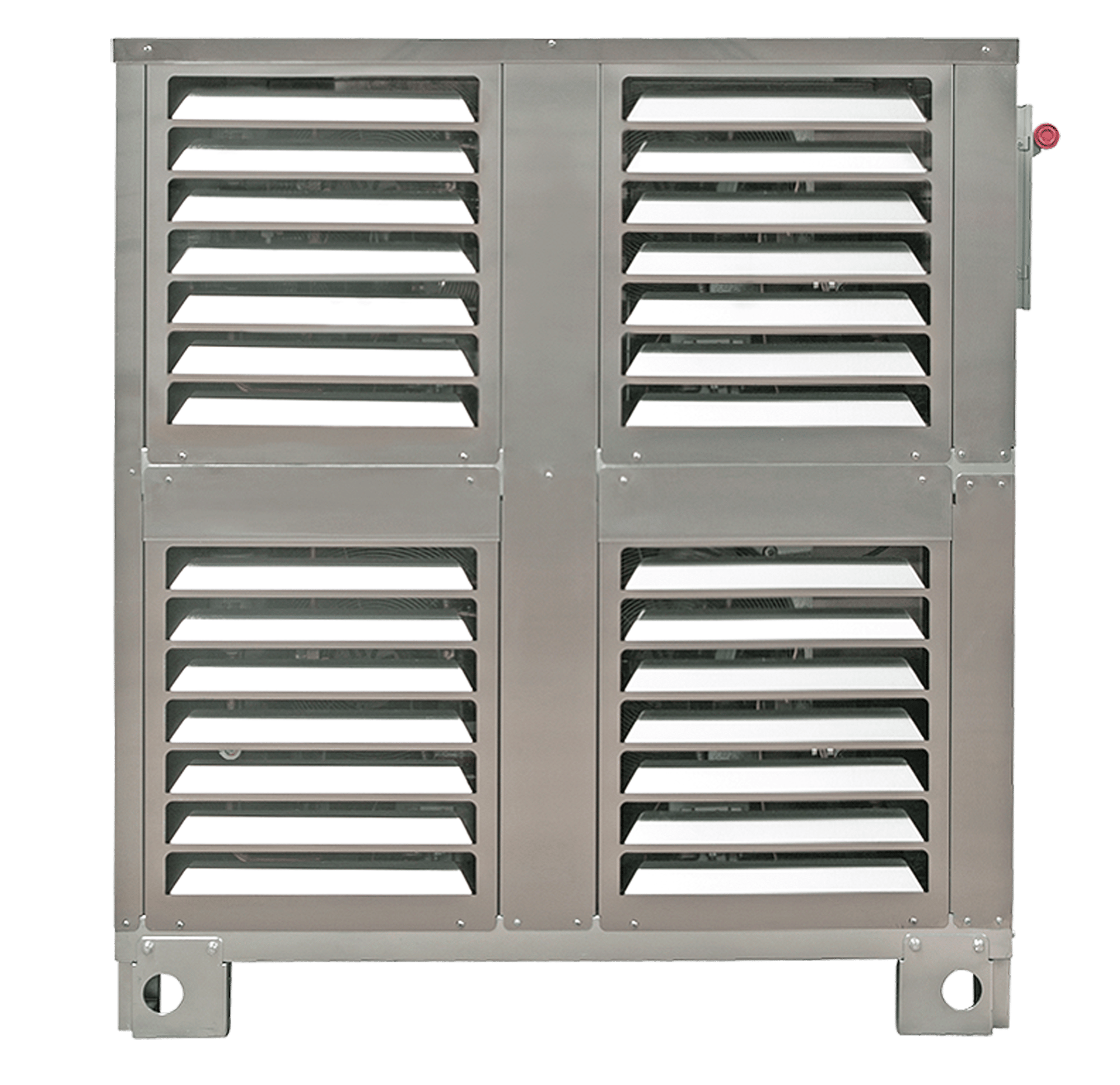

EcoCool

RDT’s EcoCool system was specifically designed to meet the ever-increasing demands for environmentally responsible compliance within the food service industry. With the Scroll Digital compressor, the EcoCool system offers precise control of individual compressors, allowing an application that would typically require eight compressors, to now utilize only two digital scroll compressors (one medium temperature and one low temperature). For the customer’s peace of mind, it also includes a back-up compressor for 100 percent redundancy. With fewer compressors, the EcoCool system has a smaller system footprint, lower refrigerant volume, lower installation costs and reduced electrical consumption.

STANDARD FEATURES

- The EcoCool system can operate all refrigeration fixtures below on only two (2) compressors

- Digital Refrigeration System

- Optimum Energy Efficiency

- 100% Redundancy

- Reduced Refrigerant Volume

- Smaller Footprint

- E2 Communication System (monitor, alarm and report)

- Lowered Installation Costs

Frequently Asked Questions

How much energy savings can RDT systems provide?

RDT systems can cut energy usage by up to 50% for foodservice operations.

Who do I contact for technical support or troubleshooting?

What is the best way to request a quote or drawing?

Submit an inquiry via the Contact Us form or email info@rdtonline.com.

How can customers get or request warranty information?

Warranty information is available on the RDT website here.

What should I know before installing an RDT system?

- Verify voltage and amperage compatibility (systems are often pre-wired).

- Ensure sufficient power supply with dedicated circuits.

- Confirm condenser airflow requirements and clearance.

- Plan for drain lines with proper slope and trap installation.

- Select refrigerants that comply with EPA/CARB/F-Gas regulations.

- Follow correct refrigerant piping layout and insulation.

- Comply with local codes and inspection requirements.

- Use licensed refrigeration contractors familiar with rack systems.

- Establish a preventive maintenance schedule (filter cleaning, leak checks, defrost calibration).

RELATED BLOGS

WANT MORE INFO?

CONTACT US TO LEARN MORE ABOUT ECOCOOL

If you're interested in learning more about the EcoCool and how it can help improve your operation, please fill out the form on this page and one of our helpful staff members will get back to you shortly!